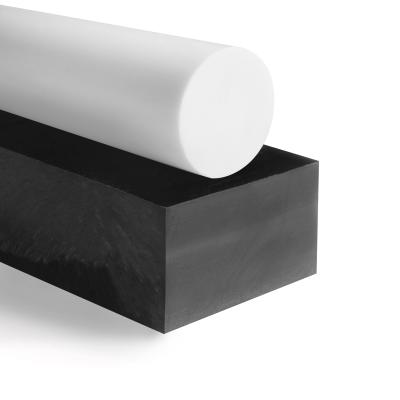

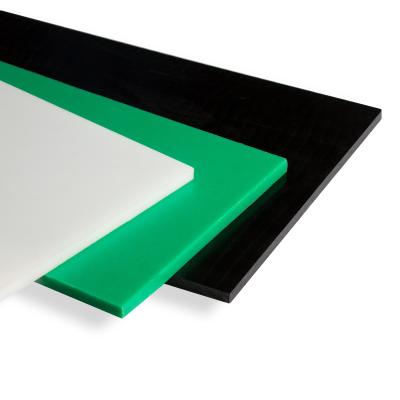

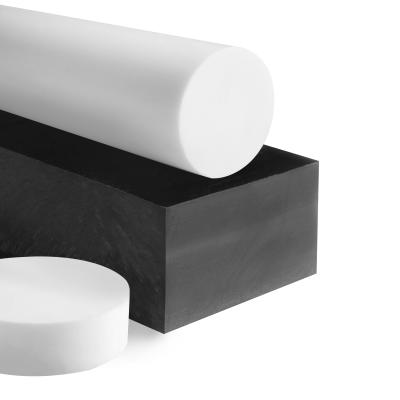

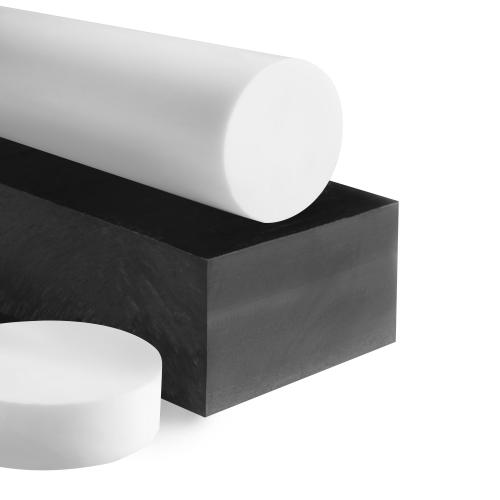

Polyoxymethylene (POM-C)

Polyoxymethylene (POM-C) has a high surface hardness and good sliding and wear behaviour. There is no tendency to stress cracking. Also, POM-C has high thermostability and chemical resistance. This material is often used in the food industry because cleaning processes require resistance to hot water and various chemicals. All bars, as well as natural and black sheets, comply with food requirements under 10/2011 / EC.

FEATURES

Pressure tested quality;

High strength and stiffness;

High thermal stability (to -40 °C);

Low water absorption;

High dimension stability;

Good electrical insulating properties;

Very good sliding properties;

High resistance to solvents;

Very high resistance to stress cracks.

APPLICATION

Bearings, fittings, gear wheels, parts for pumps, screws, bobbins, parts for the textile industry, carrier for coating lines, food industry, components in medical technology and photovoltaics as well as the electrical industry, components for filtration systems, reactor housings, sealing discs (mostly made of calendered sheets).

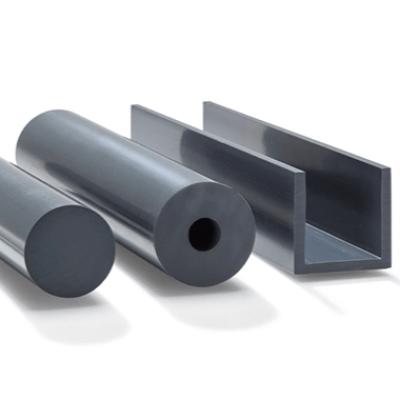

PRODUCT RANGE

Sheets: size 610x1000/2000/3000 mm, 1000x1000/2000 mm, thickness 8- 2-200 mm

Rods: length 1000/2000/3000 mm, diameter 3-500 mm